Written by Branko Babic

As the popularity of the Microblading technique began to spread across Europe, it became increasingly clear that it was just a matter of time before this technique would be banned by serious and strict EU regulations. The reason for this was that pigments manufactured in Asia, which failed to meet strict European regulations, had made their way onto the EU market. This became a huge issue, one that needed to be resolved. It was also clear to us that our artists needed pure pigments that would ensure the future of their business while giving them peace of mind in working with their clients.

The standards that would at some point come into effect in Europe were known about long before ECHA REACH 2021 came into force but back then, no one gave this much thought. The European market became flooded with pigments that contained large concentrations of heavy metals, carcinogenic aromatic amines, and illicit amounts of formaldehyde.

The battle in the marketplace concerning Microblading pigments was conducted in two ways: lighter and heavier. The position of ONE group of manufacturers was to satisfy the requirements of the Microblading artists at all costs. Phi Academy’s approach was to fight for client satisfaction.

Sounds off, doesn’t it? How can it be that artist and client requirements mismatch? Unfortunately, this was the case. PhiBrows artists never had an issue when it came to choice because they have used PhiBrows pigments from the very beginning. On the other hand, for other artists, two things were crucial in choosing pigment: one being, how easy they are to use on the skin (achieved by the inclusion of very harmful additives) and the second being price. Anything that is easily absorbed by the skin requires less work, is cheaper and on the surface, seems to be a good idea.

Fast-forward to a few years later, it turned out that the Phi Academy's policy was correct.

When I first contacted the only tattoo pigment and permanent makeup factory in Germany, I was turned away. At that time, they refused to create pigment for us, telling me openly that they were worried about losing their other customers if they were to start manufacturing for Phi Academy. I was insanely persistent. I called and called, and insisted on a meeting. I was even willing to agree to pay a huge fine if anyone in the industry discovered that they were manufacturing pigments for our company.

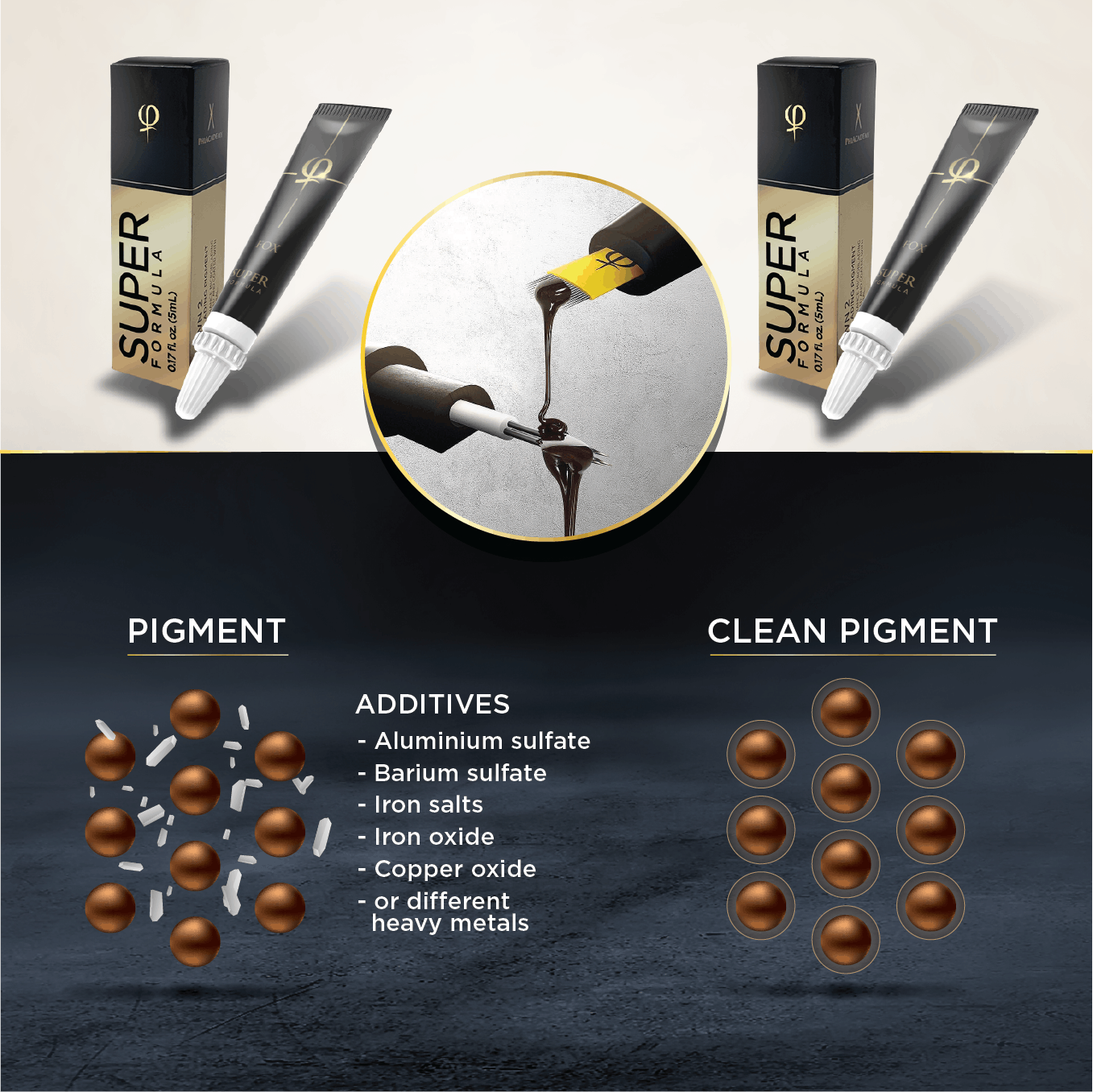

After much persistence, the factory owner agreed to meet with me. We met in Rome. As soon as I shared my ideas of what Phi pigments could be with him, something changed. His previous attitude, to categorically refuse to cooperate with us, melted away, and all of a sudden he became very motivated to work on the idea together. The idea is “pure pigment.”

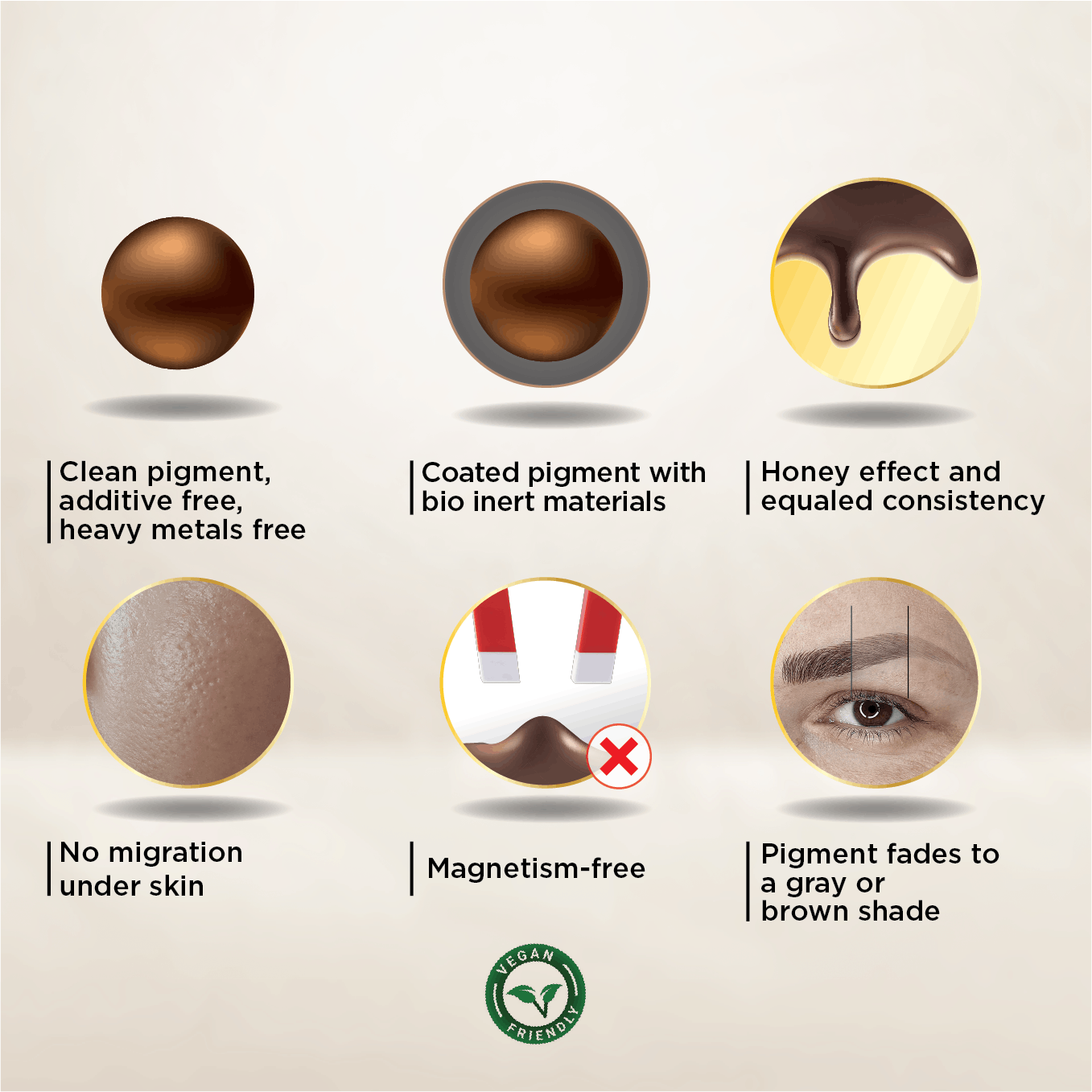

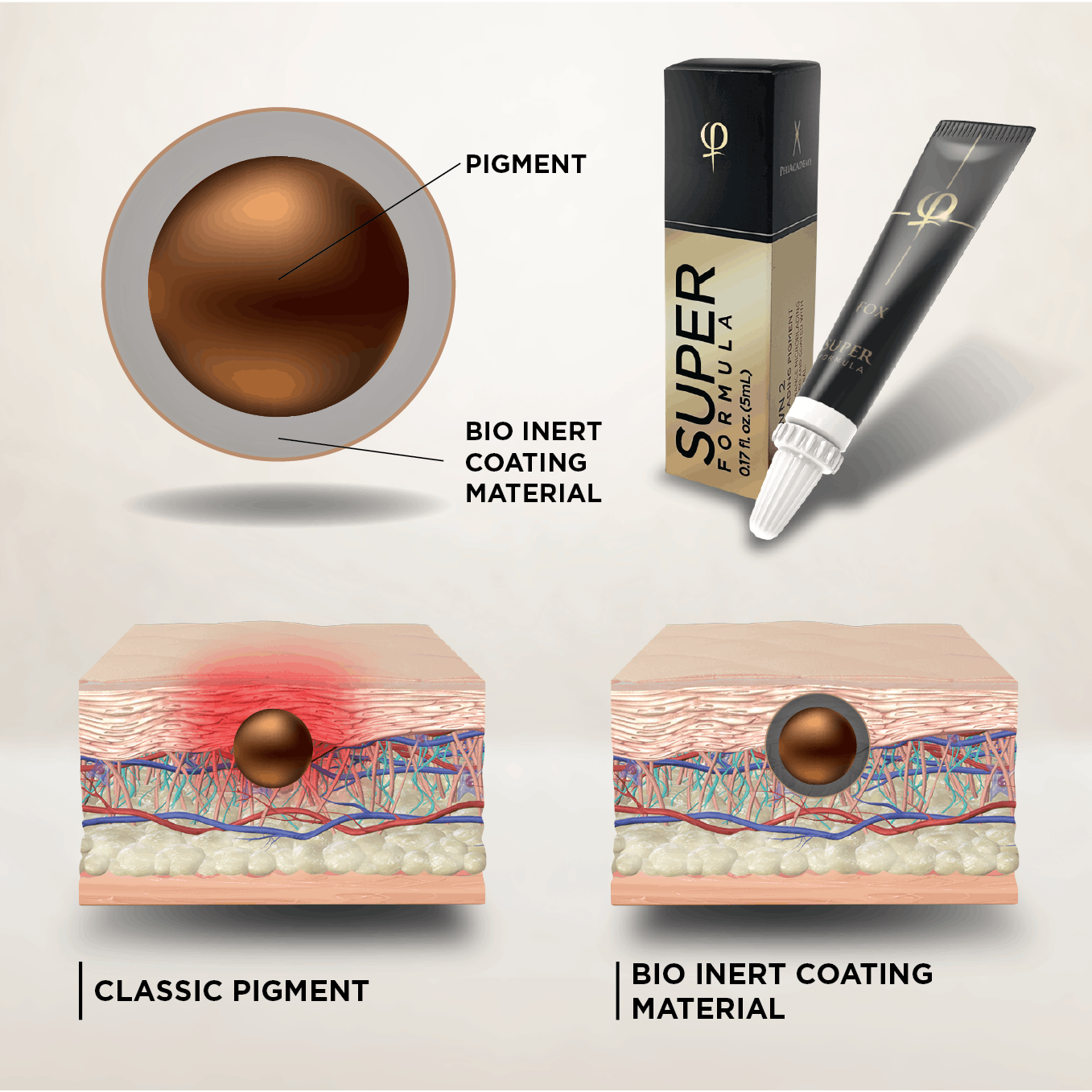

This was completely contrary to common perceptions at the time, as a market share was then obtained by providing a good price and pigments that were easy to apply. The pure pigment could meet neither of these demands. In other words, pure pigments have a longer absorption time and are costlier.

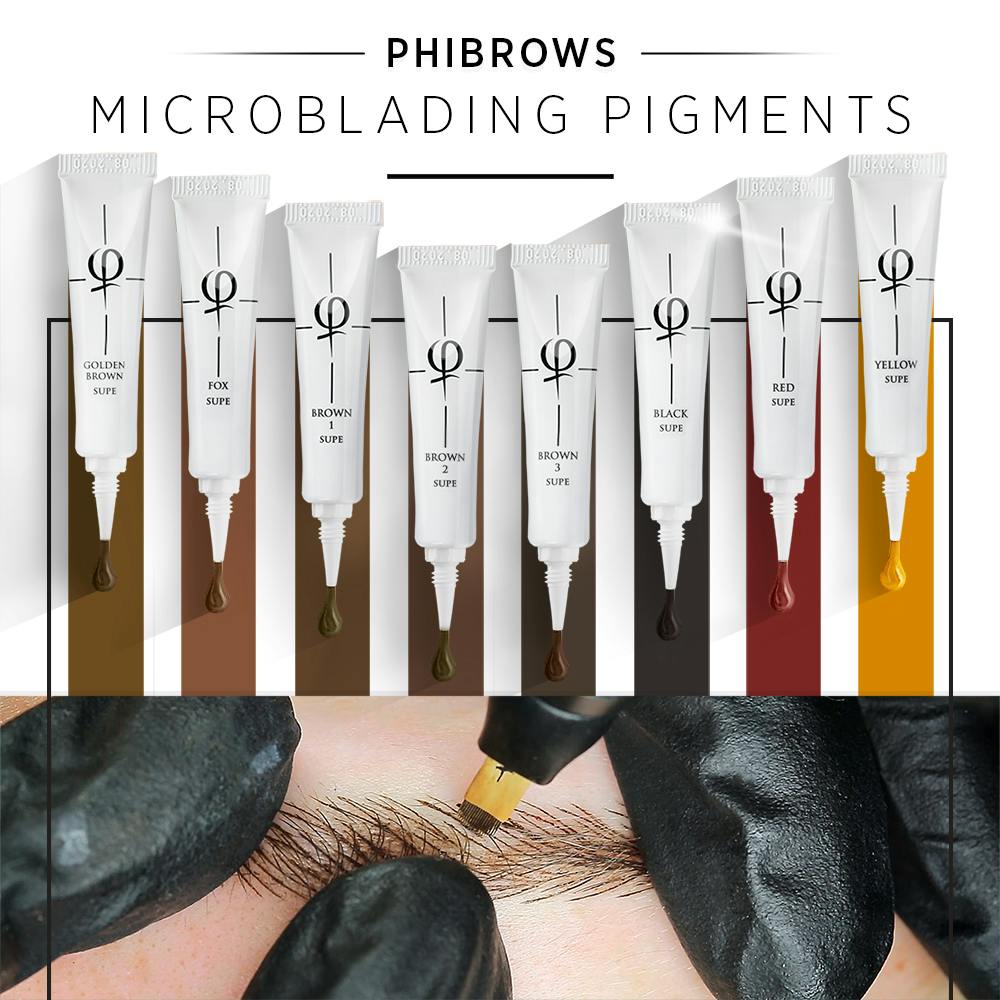

In addition to the demand for pure pigment, I had 5 other requirements to fulfill. One of which was to ensure pigment that wouldn’t turn red after a while. When the factory owner heard my list of requirements, he said: “Whoa, hold on a second, what you’re asking for will cost a lot to make, let’s take this step by step, starting with the highest priority demand first.” We ranked the demands by priority and began our “covert operation,” that is, working together in secret.

When we created the first formula which fulfilled the first of the 6 demands, he asked me, "What do you want us to call this formula?" “S,” I replied. “What does that stand for,” he asked me. "It’s the first letter of the word SUPERB, which is what the formula will be called."

As the years passed and as our demands for the formula were slowly met, "SU," "SUP," "SUPE," and "SUPER" formulas quickly appeared, one after the other. PhiBrows pigment quickly became the market leader because its formula was free from heavy metals, created from synthetically derived pigments.

At the time, everyone else was basing their pigments on Iron Oxide. Soon after, the factory began employing all of its capacity solely for the production of PhiBrows pigments. Suddenly there was no more fear of other customers causing issues, as Phi became the only important customer of pigments. And just like that, the relationship between Phi Academy and the factory was covert no more.

With the arrival of 2022, the European Chemicals Agency (ECHA) finally announced its requirements for clean and safe pigments. As of our SUPE Formula, Phi Academy has regularly fulfilled all obligatory conditions required as of today (conditions set 3 years after we started manufacturing this formula). Today, PhiBrows artists and PhiBrows clients can all sleep peacefully, while American and Asian Microblading pigments, which contain illegal amounts of formaldehyde and heavy metals, have finally been banned for sale in Europe as of this year.

Our story about safe and clean pigments doesn’t end here as Phi Academy is still working hard on manufacturing its final formula (SUPERB). All investments made in the technology necessary to manufacture pure pigments were possible thanks to Phi artists around the world who have always been faithful to the Phi brand.

Join the discussion